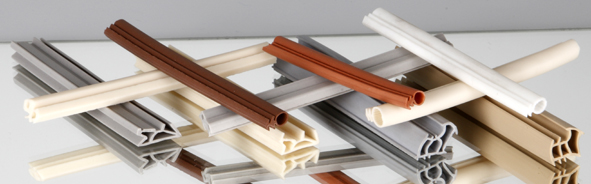

Extruded profile seals

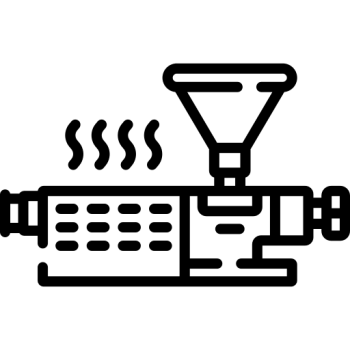

Extrusion is a manufacturing process in which materials such as rubber, plastic or silicone are extruded through a die to create long, uniform shapes with consistent cross-sections. This method involves heating a raw material and forcing it through a moulded hole, resulting in a final product with the desired dimensions. Extrusion is widely used in a variety of industries to produce gaskets and profiles such as pipes, tubing, form gaskets, offering efficiency and precision in shaping materials for a variety of applications.

Product description

Properties

Each category of gaskets has unique properties resulting from their material composition. Rubber gaskets boast elasticity and flexibility, while plastic variants offer durability and chemical resistance. Silicone gaskets excel in flexibility and heat resistance. Understanding these inherent properties is key to selecting the ideal type of gasket for specific applications.

Description

Our company produces various types of sealing profiles on several technological lines. If you are looking for a reliable partner for unrivalled expertise and customised extruded gaskets that meet your exact requirements,MAJK is your permanent partner in success. Explore our comprehensive line of customizable solutions and elevate your products to unmatched levels of performance and reliability.

Versions

Extrusion facilitates the precise creation of seals with uniform cross-sections. Raw materials such as rubber, plastic or silicone are carefully processed through dies, resulting in seals and shapes tailored to the desired specifications. This precision shape design ensures optimum performance and compatibility with a variety of industrial requirements. Final designs depend on the die shape and the requirements of the final product - from basic shapes such as square, rectangle, cord, intermediate ring or special shapes.

Material basis

Gaskets can be made from several types of homogeneous and microporous mixtures and hardnesses - depending on the conditions of use. The most common materials are EPDM, NBR, SBR, MVQ, CR, AEM, but we are not afraid of new challenges, on the contrary - we are ready and looking forward to every new development. The specific gravity ranges from 0.35 - 1.7 g/cm3 and in hardnesses from 20 to 90°ShA.

EPDM rubber gaskets

EPDM rubber gaskets/seals are renowned for their versatility and range of applications. They are designed to fill gaps in installations, absorb shock and protect against damage. EPDM rubber gaskets/seals are available in a variety of shapes and sizes to suit different needs and applications. They can be manufactured in custom sizes and shapes to meet specific requirements. This makes them ideal for use in a wide range of industries including the electrical industry, building and construction, automotive, construction, aluminium profile manufacturing, glass manufacturing and many more.

NBR rubber gaskets

If you’re looking for a seal that can withstand petroleum products and oils, then rubber gaskets and NBR seals are the ideal solution for you. NBR (nitrile butadiene rubber) is a type of synthetic rubber that is highly resistant to various mineral oils, petroleum products (gasoline, diesel, etc.) and has minimal dimensional growth. At the same time, it retains good abrasion resistance, making it an ideal choice for sealing applications in a variety of industries.

SBR rubber gaskets

SBR rubber gaskets and seals are versatile and indispensable tools used in a variety of industries. They are known for their durability, safety and versatility and are used in a variety of applications such as sealing, insulation and shock absorption. In this article, we will provide valuable information about SBR rubber gaskets and seals, including their properties, uses, and comparisons to other rubber products.

SBR rubber gaskets and seals are versatile and essential tools used in a variety of industries. With a variety of shapes, sizes and variations, SBR rubber gaskets and seals can be customized to meet specific application requirements. By understanding the features and uses of SBR rubber seals and caps, potential clients can make an informed decision when selecting the right tool for their specific needs.

Microporous rubber gaskets (SPONGE)

Microporous rubber gaskets are an innovative solution for industrial applications where traditional rubber gaskets may not work as well. These seals are made from a unique type of rubber that has a sponge-like structure, making it highly effective for sealing applications. In this section, learn more about the benefits of using sponge-like microporous rubber gaskets for industrial applications.

Silicone rubber gaskets (VMQ, FVMQ)

Silicone gaskets made from VMQ (also known as silicone rubber) or FVMQ (fluorosilicone rubber) offer many advantages in industrial applications. These materials are known for their exceptional resistance to high temperatures and harsh chemical environments, making them ideal for use in applications where other materials may not perform as well. In this section, learn more about VMQ and FVMQ silicone gaskets in industrial applications.

Profiles with metallic reinforcement (PIRELI)

Pireli metal reinforced gaskets are known for their durability and safety. They are designed to provide excellent edge protection while maintaining good sealing properties. These gaskets are ideal for use in a variety of industries where edge protection is required, including automotive, edge protection gaskets, window seals, window guides, commercial vehicle profiles and rubber clamping profiles.

Plastic profiles (PVC, uPVC)

Profiles made from soft or hard PVC are a popular choice for seals in industrial applications. These profiles are designed to suit specific applications including pipes, valves and flanges.

Thermoplastic gaskets (TPE, TPV)

Thermoplastic gaskets including TPE (thermoplastic elastomer) and TPV (thermoplastic vulcanizate) are increasingly popular for use in industrial applications. These gaskets offer several advantages over traditional rubber gaskets. For more information, please refer to this section.

Other profiles (PE, FLOCK)

Flocked gaskets are widely used in industrial applications due to a unique combination of properties that make them highly effective in sealing applications.

Polyethylene (PE) gaskets are widely used in industrial applications due to their exceptional physical properties. PE is a thermoplastic polymer that is widely used in various industries due to its versatility and durability.