The connection of profiles into o-rings currently takes place in two forms:

- by gluing joints

- by vulcanizing joints

Bonding joints

- in this production process, the required length of seal is cut according to your requirements (the joint can be either perpendicular or oblique to ensure stronger adhesive joints)

- then the profile is cleaned and, if the material requires it (eg silicone seals) a primer is applied (a substance ensuring significantly better tack of joints)

- the next step is the gluing with a second glue.

- the last production step is to check the joint by a tensile test

Vulcanized joints

- this process is much more difficult

- as with gluing the joints, the first step is to cut to the required length

- then comes the cleaning

- preparation of raw mixture for vulcanized joint

- vulcanization itself

- modification of vulcanized joint

- joint inspection and testing

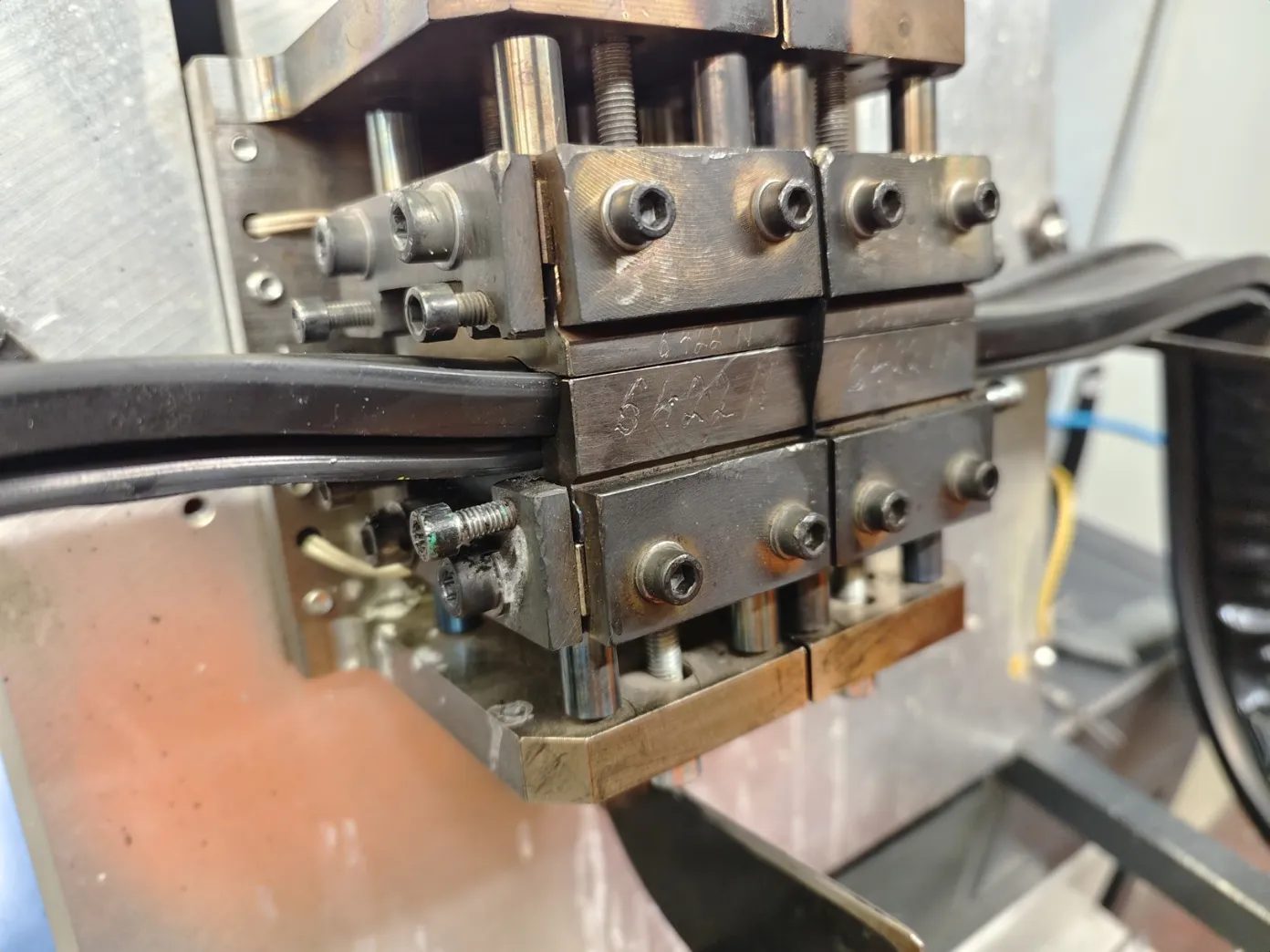

The whole process takes place on special single-purpose vulcanizing presses. The great advantage of this process is the improvement of the dynamic properties of the joint and the possibility of producing o-rings from 350 mm to several meters