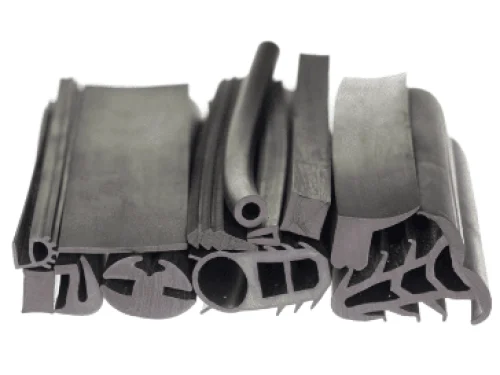

NBR rubber seals

Hard – compact seals resistant to oil, petrol, diesel and the like.

PRODUCT DESCRIPTION

Description and use

Description and use – the most common use is as a sealing element in various industries where special resistance to petroleum products and oils is required.

Properties

Properties – gaskets are characterized by excellent resistance to various mineral oils, petroleum products (petrol, diesel, etc.), where there is minimal enlargement. At the same time, the gaskets retain good abrasion resistance. However, these gaskets do not have good resistance to benzene, aromatic, ester, and chlorinated hydrocarbons. They are resistant to temperatures ranging from -40 °C to +90 °C.

Performances

Design – they are produced in several basic shapes, such as square, rectangle, circular gasket, intermediate ring, or specific shapes. Gaskets can also be made as self-adhesive.

Material basis

Material basis – these gaskets can be made of several types of homogeneous mixtures and hardnesses – depending on the conditions of use. The specific weight is around 1.3 g / cm 3 and hardness from 40 to 80 °ShA. In addition to standard materials meeting various demanding applications, we can also produce peroxide mixtures (sulfur-free), non-flammable profiles in terms of (NF F 16-101, ISO 45545), products in terms of TL1010 and FMVSS 302, water supply materials set by EN681, gaskets for flood-protection walls, automotive gaskets according to VW 2.8.1

Technical documentation

Description and use

Description and use – the most common use is as a sealing element in various industries where special resistance to petroleum products and oils is required.

Properties

Properties – gaskets are characterized by excellent resistance to various mineral oils, petroleum products (petrol, diesel, etc.), where there is minimal enlargement. At the same time, the gaskets retain good abrasion resistance. However, these gaskets do not have good resistance to benzene, aromatic, ester, and chlorinated hydrocarbons. They are resistant to temperatures ranging from -40 °C to +90 °C.

Performances

Design – they are produced in several basic shapes, such as square, rectangle, circular gasket, intermediate ring, or specific shapes. Gaskets can also be made as self-adhesive.

Material basis

Material basis – these gaskets can be made of several types of homogeneous mixtures and hardnesses – depending on the conditions of use. The specific weight is around 1.3 g / cm 3 and hardness from 40 to 80 °ShA. In addition to standard materials meeting various demanding applications, we can also produce peroxide mixtures (sulfur-free), non-flammable profiles in terms of (NF F 16-101, ISO 45545), products in terms of TL1010 and FMVSS 302, water supply materials set by EN681, gaskets for flood-protection walls, automotive gaskets according to VW 2.8.1

Technical documentation

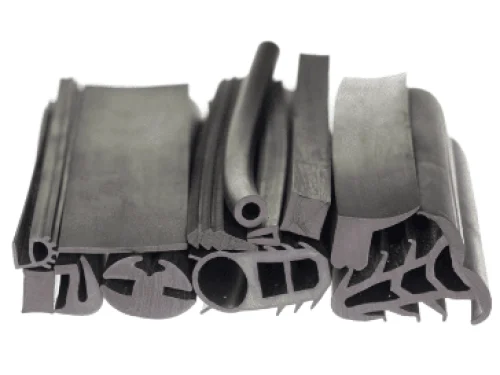

NBR rubber seals

Hard – compact seals resistant to oil, petrol, diesel and the like.

PRODUCT DESCRIPTION

Description and use

Description and use – the most common use is as a sealing element in various industries where special resistance to petroleum products and oils is required.

Properties

Properties – gaskets are characterized by excellent resistance to various mineral oils, petroleum products (petrol, diesel, etc.), where there is minimal enlargement. At the same time, the gaskets retain good abrasion resistance. However, these gaskets do not have good resistance to benzene, aromatic, ester, and chlorinated hydrocarbons. They are resistant to temperatures ranging from -40 °C to +90 °C.

Performances

Design – they are produced in several basic shapes, such as square, rectangle, circular gasket, intermediate ring, or specific shapes. Gaskets can also be made as self-adhesive.

Material basis

Material basis – these gaskets can be made of several types of homogeneous mixtures and hardnesses – depending on the conditions of use. The specific weight is around 1.3 g / cm 3 and hardness from 40 to 80 °ShA. In addition to standard materials meeting various demanding applications, we can also produce peroxide mixtures (sulfur-free), non-flammable profiles in terms of (NF F 16-101, ISO 45545), products in terms of TL1010 and FMVSS 302, water supply materials set by EN681, gaskets for flood-protection walls, automotive gaskets according to VW 2.8.1

Technical documentation

Description and use

Description and use – the most common use is as a sealing element in various industries where special resistance to petroleum products and oils is required.

Properties

Properties – gaskets are characterized by excellent resistance to various mineral oils, petroleum products (petrol, diesel, etc.), where there is minimal enlargement. At the same time, the gaskets retain good abrasion resistance. However, these gaskets do not have good resistance to benzene, aromatic, ester, and chlorinated hydrocarbons. They are resistant to temperatures ranging from -40 °C to +90 °C.

Performances

Design – they are produced in several basic shapes, such as square, rectangle, circular gasket, intermediate ring, or specific shapes. Gaskets can also be made as self-adhesive.

Material basis

Material basis – these gaskets can be made of several types of homogeneous mixtures and hardnesses – depending on the conditions of use. The specific weight is around 1.3 g / cm 3 and hardness from 40 to 80 °ShA. In addition to standard materials meeting various demanding applications, we can also produce peroxide mixtures (sulfur-free), non-flammable profiles in terms of (NF F 16-101, ISO 45545), products in terms of TL1010 and FMVSS 302, water supply materials set by EN681, gaskets for flood-protection walls, automotive gaskets according to VW 2.8.1