Elastomeric and sliding bearings

Dilatation of building concrete structures, in other words bridge bearings reinforced with sheet metal or sliding bearings with PTFE coating.

What are elastomeric bridge bearings and PTFE plain bearings?

Description

Elastomer bearings

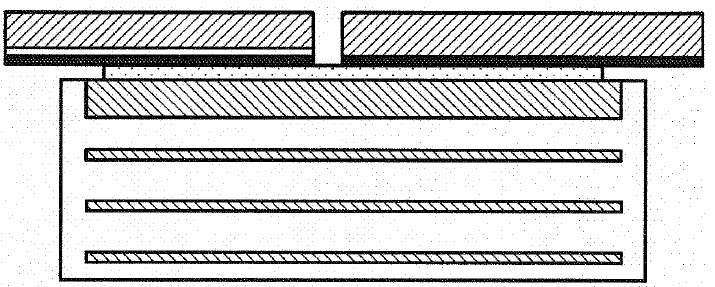

Rubber bridge bearings used in the construction industry today are sophisticated products made from the highest quality materials. Elastomeric bearings are constructed in layers and are manufactured in high-performance presses. They are composed of CR (chloroprene rubber) or NR (natural rubber) according to the required standard and steel plates between these rubber layers.

According to project requirements or our customers' requirements, we can produce elastomer bearings in cylindrical, square or rectangular shape. We design our elastomer bearings according to the latest knowledge and technical developments in bearing technology.

In addition to high-quality rubber, the basis is metal sheets, the quality of which is also determined by the relevant standard or customer requirements. These materials, stacked on top of each other in a mould, are bonded together by a high-pressure bonding process in a press called vulcanisation. In this way, the rubber adheres to the metal depending on the pressure and force applied.

Plain bearings with PTFE plates

Slide-slide bearings play a very effective role in the point solutions of the design used. Sliding-type bearings with Teflon plates are used in high detail solutions that have no small horizontal displacements except for vertical loads.

Properties

Elastomer bearings

MAJK bridge bearings are subject to quality control before and after production in accordance with European standards. Elastomer bearings can be manufactured in accordance with AASHTO M251, EN 1337, BS 5400, DIN 4141, TS-ISO 6446 and AS 5100-4 standards depending on our customers' requirements.

Plain bearings with PTFE plates

For all plain bearings with Teflon plates, it is necessary to use steel plates that do not affect the displacement. Generally, this type of bearing can be encountered in buildings, shopping malls and on bridges.

Horizontal loading never affects this type of bearing. The horizontal load is transferred directly to the oil spaces that occur on PTFE materials with silicone oil, which can protect its own integrity and also reduce friction with the stainless steel plate.

Versions

From small sizes up to 1000×1000 mm sizes, different thicknesses but also special designs.

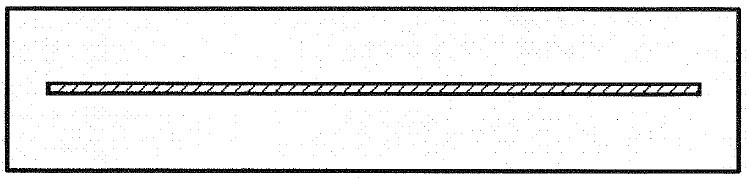

ELASTOMERIC BEARING TYPE A

- layered bearing with only one steel reinforced plate, fully covered with elastomer (rubber)

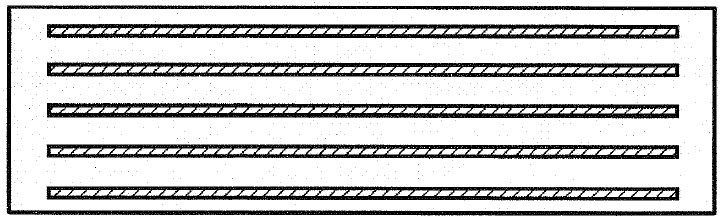

ELASTOMER BEARING TYPE B

- layered bearing with at least two steel reinforced plates fully covered with elastomer (rubber)

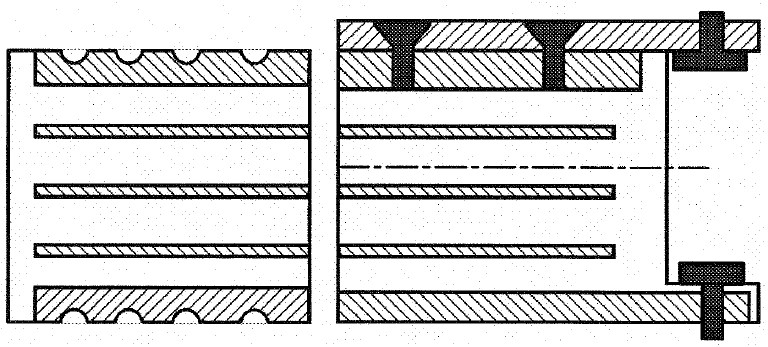

ELASTOMER BEARING TYPE C

- layered bearing with outer steel plates (profiled or enabling fixing)

ELASTOMER BEARING TYPE D

- a layered bearing with at least two steel reinforced plates fully covered with elastomer (rubber) but with a PTFE layer bonded to the elastomer

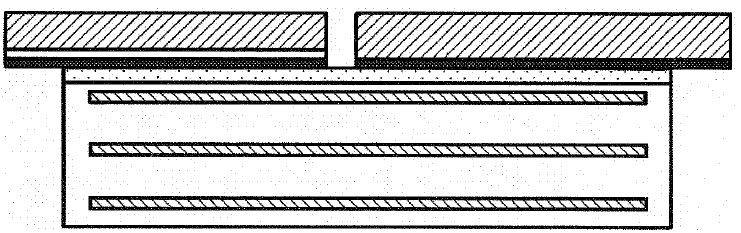

ELASTOMER BEARING TYPE E

- layered bearing with outer steel plates (profiled or allowing fixing) but with one outer plate glued to the elastomer and a PTFE layer embedded in the steel

ELASTOMERIC BEARING TYPE F

- unreinforced block and strip elastomer bearing

Material basis

Certified CR (chloroprene rubber) or NR (natural rubber) to AASHTO M251, EN 1337, BS 5400, DIN 4141, TS-ISO 6446 and AS 5100-4.